Categories

25P Integrated Closed-Loop Nine-Fans Dryer

- Heating capacity:90kW

- Dehumidification capacity:75kW

- Max Outlet Air Temp: 85℃

- Power Supply: 380V/50Hz/3ph

- Refrigerant:R134A

(1)Introduction to Heat Pump Drying Technology

Heat pump drying systems come in various forms. Based on the circulation of the drying medium (air), they can be classified into three types: open-loop, partial exhaust air recirculation, and closed-loop systems. For biological materials that require low drying temperatures, closed-loop heat pump drying systems are currently widely used.

The closed-loop heat pump drying system consists of two working cycles: the refrigerant cycle within the heat pump system and the drying cycle of the drying medium. The refrigerant absorbs heat from the exhaust air discharged by the drying system in the evaporator, causing the liquid to evaporate into vapor. After being compressed by the compressor, it is sent to the condenser. Under high pressure, the heat pump working fluid condenses and liquefies, releasing high-temperature condensation heat. This heat is used to warm the low-temperature dry air that has been cooled and dehumidified by the evaporator. The air is heated to the desired temperature and then introduced into the drying chamber for recirculation as the drying medium. The liquefied heat pump working fluid then returns to the evaporator through the expansion valve, and the cycle repeats. Meanwhile, most of the water vapor in the exhaust air is condensed directly in the evaporator and drained away.

The heat pump section of this system uses an auxiliary condenser. This structure has several advantages. It allows flexible and convenient control of the drying temperature. The auxiliary condenser also has a high heat transfer coefficient and does not require a specially designed heat exchanger. Additionally, if the auxiliary condenser is used to heat outside air for pre-drying of materials, the higher-temperature condensation heat can be recovered, saving energy and improving system efficiency. The purpose of setting a bypass in the evaporator is to ensure that the wet and hot air passing through the evaporator can better match the refrigeration capacity of the evaporator, fully utilizing its dehumidification capability. It also helps to balance the heat load between the condenser and the evaporator, reducing losses and enhancing the heat transfer of the condenser, thus meeting the requirements of both the heat pump and drying units.

(2)Characteristics of Heat Pump Drying Technology

Energy Saving

Energy saving was the original motivation for the application of heat pumps and remains one of its main advantages. When drying wood at low temperatures (15–45°C), heat pumps can save 40–70% of energy. The suitable drying temperature for rice is 35–50°C. Although the temperature is low, a large amount of heat is required. Traditional dryers have an efficiency of only 3–5%, while heat pump dryers can significantly improve efficiency. For textiles, which have strict drying temperature requirements, heat pump drying units not only meet these requirements but also save about 50% of energy compared to traditional drying units. In the case of vegetable dehydration, heat pump drying can achieve energy savings of up to 90%. In recent years, more and more researchers have confirmed the energy-saving characteristics of heat pump drying units.

High Quality of Dried Products

Heat pump drying is a gentle drying method that is close to natural drying. The evaporation rate of surface moisture is similar to the rate at which internal moisture migrates to the surface, resulting in high-quality dried products with good color and high-grade appearance. Compared to ordinary drying methods, heat pump drying retains more volatile aromatic substances, heat-sensitive vitamins, and maintains better color. For example, ginger dried in a drum dryer has a gingerol retention rate of only 20%, while ginger dried using a heat pump has a retention rate as high as 26%. Experiments by Van Blarcom and Mason showed that even at 50°C, macadamia nuts dried using heat pump technology did not exhibit browning and better retained their original color, flavor, and nutritional components.

Easy and Wide-Range Control of Drying Parameters

During the heat pump drying process, the temperature, humidity, and flow rate of the recirculating air can be precisely and effectively controlled. The temperature control range is -20–100°C (with an auxiliary heating device), and the relative humidity control range is 15–80%, making it suitable for the drying of heat-sensitive materials.

Environmentally Friendly

Material drying not only requires improving product quality and saving energy but also being environmentally friendly. Compared to the CO₂ emissions from electricity, the impact of heat pumps on global warming is much smaller. This environmental friendliness is an advantage of heat pump drying. Currently, the use of heat pumps is advocated abroad to reduce CO₂ emissions, and its application is bound to increase further.

(3)Principle of High-Temperature Heat Pump Drying

Heat pump drying equipment consists of a heat pump system and a hot air drying circulation system. The heat pump system provides high-temperature heat sources for the hot air drying system and reduces the humidity of the hot air. It supplements the heat losses in the system. The hot air drying system provides the heat required for water evaporation through the circulation of hot air in direct contact with the material and removes moisture from the material. A “heat pump” is an energy-saving device that consumes a certain amount of mechanical work to absorb low-grade heat energy from the environment or waste and convert it into usable heat energy. Just like a “water pump,” which consumes a certain amount of mechanical work to lift water from a lower level to a higher level. The heat pump system consists of a compressor, condenser, throttling device, and evaporator. The working fluid in the system absorbs heat from the wet and hot air discharged from the drying chamber in the evaporator, evaporating from low-pressure liquid to low-pressure vapor. After being compressed by the compressor, it becomes high-temperature and high-pressure vapor. In the condenser, the high-temperature and high-pressure working fluid vapor releases heat to warm the air entering the drying chamber, and the working fluid itself condenses from gas to high-pressure liquid. Through the throttling device, the liquid working fluid experiences a throttling effect, reducing its pressure and temperature to become low-pressure and low-temperature liquid, and then re-enters the evaporator to absorb heat from the wet and hot gas. This cycle repeats, transferring low-temperature heat to the high-temperature medium, forming a heat pump cycle.

(4)Characteristics of Heat Pump Drying

Low Energy Consumption Costs

Heat pump drying devices can recover both the sensible and latent heat from wet and hot air during operation. The energy is fully and efficiently utilized, making it a widely recognized high-efficiency and energy-saving device.

Non-Polluting

The entire heat pump drying process takes place in a closed system. There is no need to discharge moisture to the surrounding environment, nor will harmful or foul-smelling gases be emitted. If the feeding and discharging systems are also enclosed in pipes, the entire operation can be kept in a clean environment. Compared with other drying methods, this is a unique advantage.

High Drying Quality

The drying medium in the heat pump drying device circulates in a closed space. It is not affected by external climatic conditions and operates stably under the same conditions throughout the year, resulting in high-quality drying.

相关产品

-

30HP Closed Loop Upper Outlet Units

- Heating capacity:108kW

- Dehumidification capacity:90kW

- Max Outlet Air Temp: 85℃

- Power Supply: 380V/50Hz/3ph

- Refrigerant:R134A

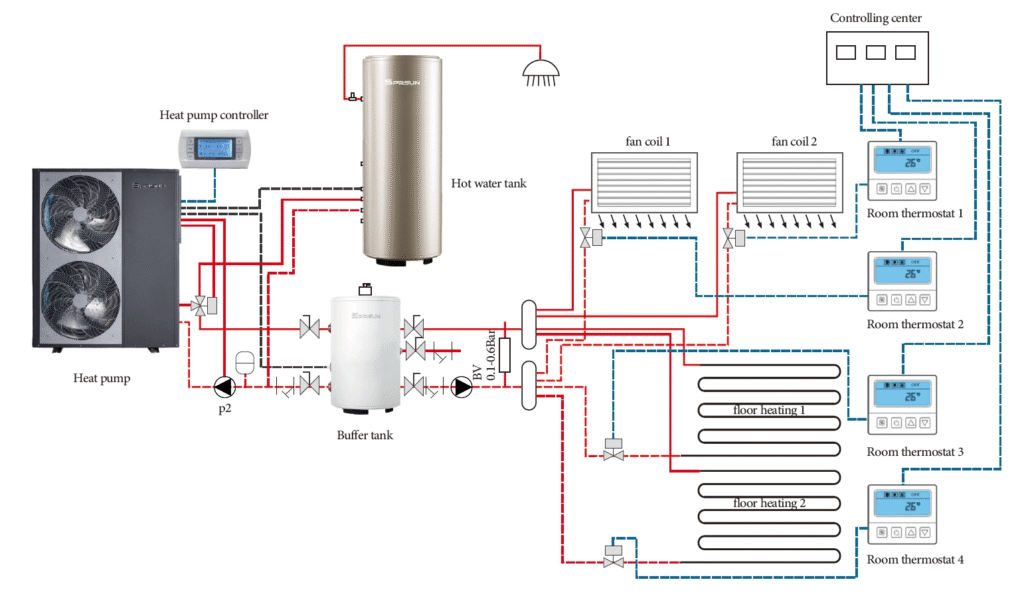

Heat Pump Installation System

Basically, the heat pump is mounted outdoors in a central position with connections to the water tank, heat pump kit, and buffer tank, which are linked to the various fan coils. Easy Installation helps to realize heating, hot water, and cooling integration solution.